URR perfectly integrates uniform air velocity controlling technology with Internal retention ring system, URR system remain round and taut when deflated, absorbing all advantages of both products, It presents more stable inner air velocity, more balanced inner pressure, better visual pleasing effect, easier installation and higher cost efficiency.

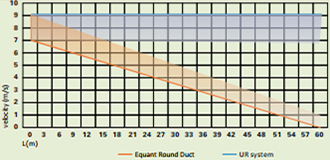

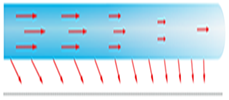

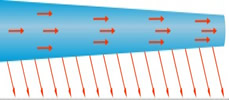

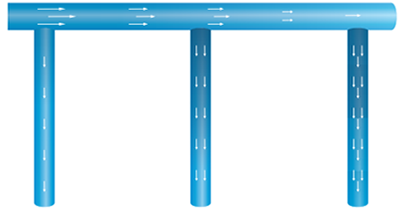

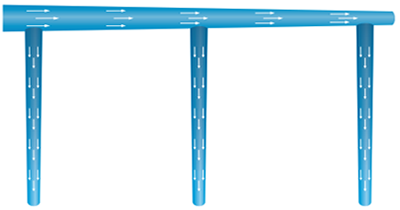

Under the same air supply condition, the internal air velocity curve of ordinary equant round duct is sharply descendant along with lengthwise direction, the air velocity tends to zero at the end cap; UR system can generally ensure stable internal air velocity.

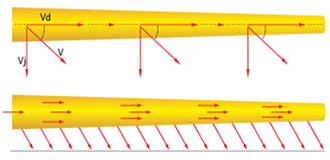

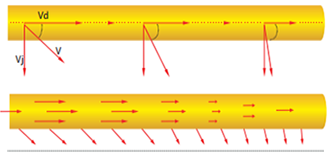

Uniform air velocity inside UR system results in same air dispersion direction along the duct.

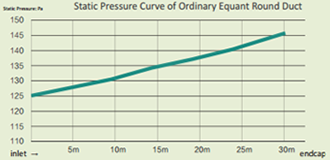

Due to vector superposition effect, there is wide difference in internal air velocity from inlet to end cap of ordinary equant round duct.

More stable inner air velocity

Generally speaking, the air velocity is rapidly decreasing inside ordinary equant round duct. Since the static pressure regain leads to the increasing of dynamic pressure whereas less on-way resistance, the overall static pressure from inlet to end cap has a certain increase. PAD must be installed to balance static pressure.

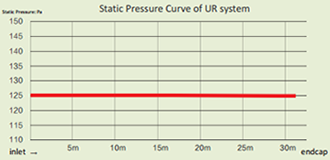

Since UR system is cone-shaped from inlet to end cap, its on-way resistance is larger than that of ordinary equant round duct. Meanwhile, the internal air velocity is relatively uniform and the static pressure regain is lower. The test result turns out that UR system could basically achieve balanced inner static pressure as long as it is not exceptionally long.

More balanced inner pressure

If ordinary equant duct is running with excessively high surrounding temperature or over-length, the inner air temperature lengthwise has a certain rise.The degree of temperature rise is relevant to duct length and temperature difference between insideand outside duct surface.

The relatively high axial air velocity of UR system reduces the heating exchange time between the inner air and duct surface, which slows down and reduces the temperature rising. Meanwhile, as the decreasing of surface area along the rear duct results in smaller heating exchange contact area, that is conducive to further slow down and reduce temperature rising. The test result turns out that the temperature rising control efficiency of UR system has been improved for 70% compared with Ordinary equant round fabric duct.

Effectively slow down temperature

Different air velocity in main duct of Ordinary equant round fabric duct leads to different airflow supply in each branch, which causes the nearer the branch is to endcap, the more airflow the branch is to receive. ACD is required to balance airflow in each branch.

Since the air velocity in main duct of UR system is completely stable and balanced while the included angle between duct surface and branch duct is slightly less than 90°, that is conducive to lead uniform air distribution to each branch.

Achieve more uniform airflow distribution

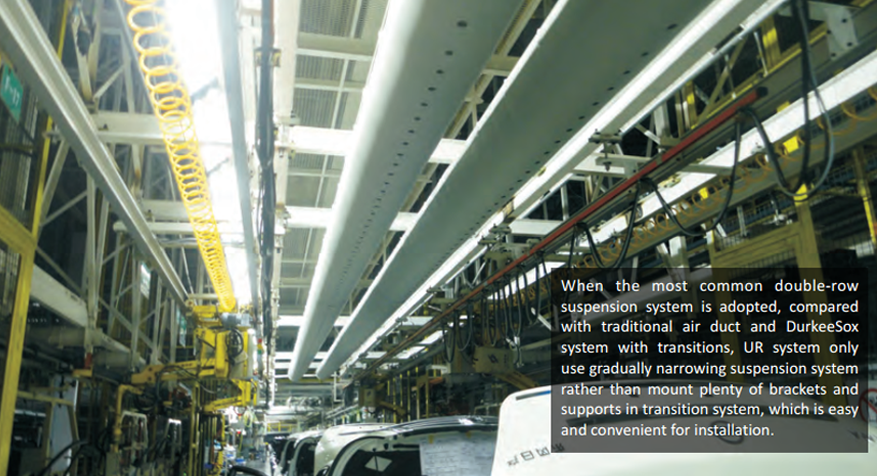

Compared with transition system, UR system is more convenient for installation.

More aesthetic than large-size duct or long duct with transition

Given high ambient temperature, large airflow and relatively long duct in such areas as machining workshop and automobile factory, URR air dispersion system maintains high and uniform inner air velocity by continuously changing conicity to achieve even air dispersion and significantly reduce temperature rising.

Given large airflow and high ambient temperature in high and large stadium and automobile workshop, UR air dispersion system is applied to obtain higher air velocity at each orifice and longer air throw distance with simple and aesthetic appearance.

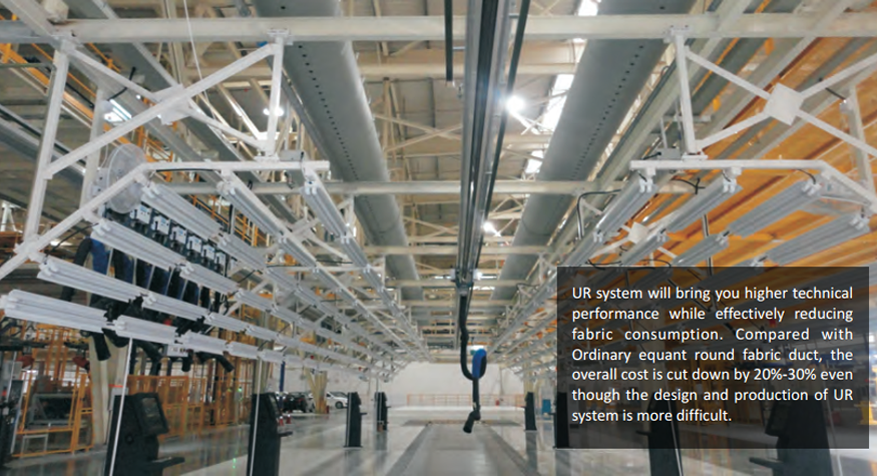

Given the high requirement of even air dispersion along the duct and strict control of terminal air velocity, the global leading design software Isox5.0 is used to calculate and generate continuously variable diameter UR system to identify as the best uniform velocity air dispersion system

Given the high space and large airflow in such areas as pharmaceutical logistics warehouse and cold chain logistics, both effective air dispersion and cost efficiency shall be taken into consideration. UR air dispersion system can not only ensure even air dispersion but also reduce overall cost because of less fabric consumption, which improves cost efficiency.